LU-222 ADVANCED LAB SPRAY DRYER MACHINE

FEATURES

- GMP Unit.

- SS Drying Chamber-Cyclones.

- Solvent/Aqueous Feeds.

- Co Current Spray.

- Twin Cyclones.

- RS 232/485 Port.

- Capacity 1 kg/hr Water Evaporation.

LU-228 LAB SPRAY DRYER MACHINE

FEATURES

- GMP Unit.

- SS Drying Chamber-Cyclones.

- Co Current Spray.

- Twin Cyclones.

- PLC Touch Screen.

- RS 232/485 Port.

- Capacity 1 kg/hr Water Evaporation.

- A Total Plant on wheels with best Yeilds.

FREEZE DRYER MACHINE

Introduction

Freeze Dryer, also known as lyophilisation or cryodesiccation, is a low temperature dehydration proces that involves freezing the product, lowering pressure, then removing the ice by sublimation. This is in contrast to dehydration by most conventional methods that evaporate water using heat.

Freeze Dryer results in a high quality product because of the low temperature used in processing. The original shape of the product is maintained and quality of the rehydrated product is excellent. Primary applications of freeze Dryer include biological (e.g, bacteria and yeasts), biomedical (e.g, surgical transplants), and food processing (e.g, coffee) and preservation.

Spray Dryer Cum Spray Congealing System

Introduction

- Spray congealing is a simple and versatile method to produce particles of desired particle size distribution by making a molten feed with desired excipients.

- Spray Congealing System, otherwise known as spray chilling/ prilling, has attracted increasing attention because it is a simple technique, less time and energy consuming compared to other methods to obtain desired particulates with desired analytical results.

PLANT SPRAY DRYER 50 - 500kg

Introduction

- Spray Drying is a continuous, quick, eficient process for drying of clear solutions / emulsions / agglomeration / suspension under controlled variable parameters with best produce repeatability results to achieve desired analytical / physical properties of produce

- Spray drying can be co-current / counter current

- The spray drying can be with air as drying media or with inert gas as drying media, categorized as Open Loop Spray Drier or Closed Loop Spray Drier respectively.

- For continuous operations of Lab spray dryer the standard unit with mono bag ilter can be replaced with auto-dedusting multi-bag ilter

Spray Dryer Close Loop

Features

- Closed Loop System

- Two Room Concept

- Aceptic GMP/ FLP Unit

- Solvent Feed

- Solvent Condensation/ Separation

- Oxygen % Control

- Mono Cyclone

- PLC – FLP IPC

- Compliance Of 21 CFR Part 11

- Capacity 5 kg/ hr Solvent Evaporation Rate

PLANT FREEZE DRIER-300

Introduction

Freeze drying is based on sublimation of a frozen solid sample, where the ice / moisture changes directly to vapour form, without going through a liquid phase. It is the only best method of drying to get < 1% residual moisture content in the produce. The produce is assured to have its original properties like taste / aroma and the analytical properties as applicable with minimum shelf life of > 12 months.

CONCEPTUAL INTRODUCTION SPRAY DRYING

(SIMPLIFIED 1 VERSION)

PURPOSE

To Spray Dry the clear feed solutions of fully dissolved particulates / Suspensions / emulsions / agglomeration in controlled conditions to develop a particulate of desired analytical & physical properties.

ABOUT SPRAY DRYING PROCESS

- - It is a continuous process that can be used as batch process.

- - The retention period of particulates under drying in the system is < 0.21 sec.

- - The vapour cloud is developed around the atomized liquid globule under drying and due to poor co-efficient of heat transfer from the external heat in drying chamber through the vapour cloud to the particulates under drying being less; the particulates under drying are not subjected to high drying inlet temp. & do not get affected / degraded.

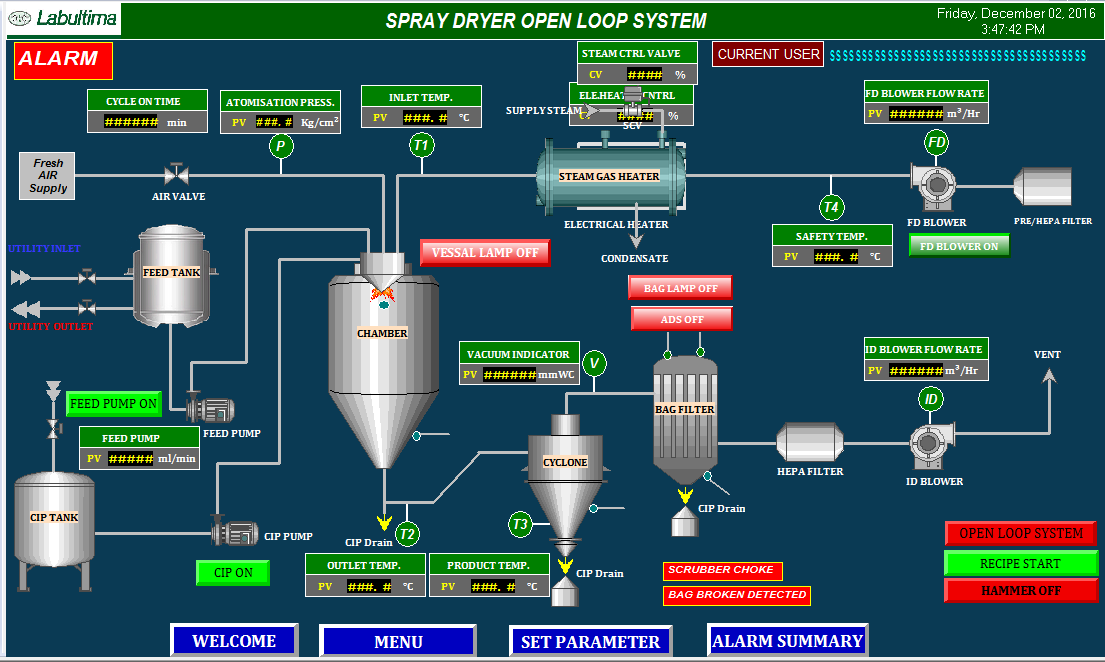

BASIC CONFIGURATIONS OF SPRAY DRYING SYSTEMS OPEN LOOP

OPEN LOOP

Ambient air is used as a heating media to dry aqueous feeds. The fresh ambient air is sucked through a hepa filter for heating the air in direct / indirect heating system for drying & after separation of the dried particulates it is exhausted to atmosphere.TYPICAL P & I D OF OPEN LOOP SPRAY DRYING SYSTEM / SCREEN SHOT OF HMI

NOMENCLATURE

VARIABLE PARAMETERS

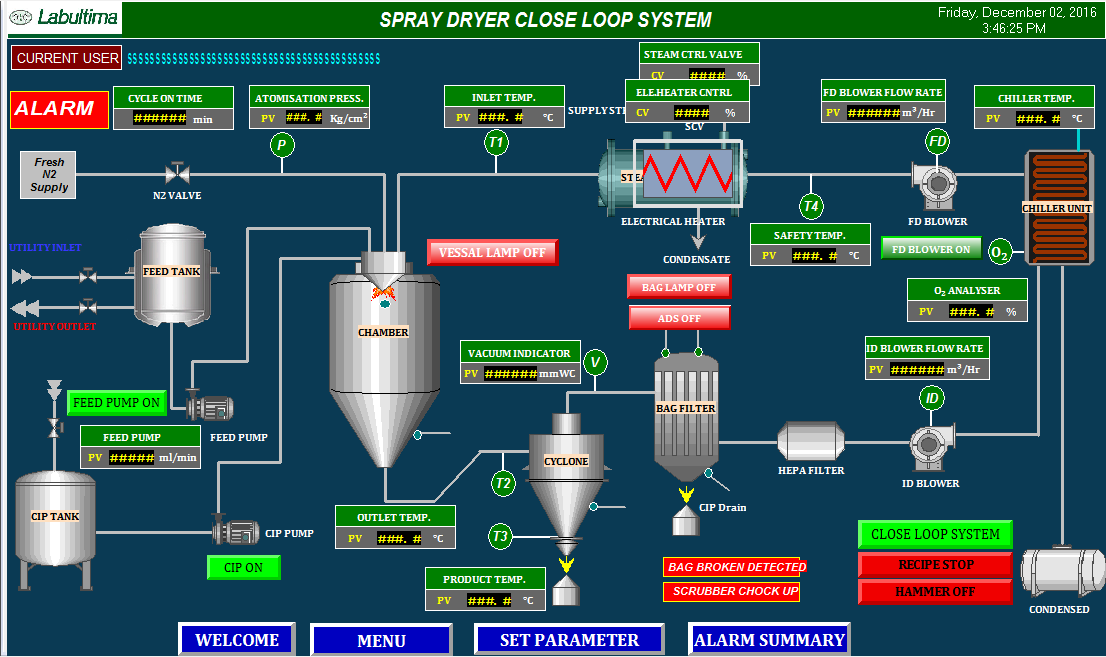

BASIC CONFIGURATIONS OF SPRAY DRYING SYSTEMS CLOSED LOOP

CLOSED LOOP

TYPICAL P & I D OF CLOSED LOOP SPRAY DRYING SYSTEM / SCREEN SHOT OF HMI

NOMENCLATURE

VARIABLE PARAMETERS

CONTROL SYSTEM

TYPES OF INSTALLATIONS FOR OPEN LOOP OR CLOSED LOOP SPRAY DRYING SYSTEM

- Single Room Concept : Where total spray drying system, equipment including FD/ID Blowers, Hepa Filters, Control Panel, chilling unit is located in single clean to atmosphere room.

- Two Room Concept : Where only the Drying Chamber / Cyclone & Bag Filter are located in clean room & the FD/ID Blowers, Hepa Filters, Control Panel, and Chilling Unit are located in service area outside clean room.

CIP SYSTEM

SIP SYSTEM

PRODUCE

- Crystalline form

- Amorphous form

- Encapsulated form

- Englobed form

- Compatible for targeted delivery form

- Slow release form

- Nano particles form

- Granules form

TYPES

- Standard Spray Drier : Having L/D ratio between 1:1 to 1:3 where “D” is inner diameter of the drying chamber & “L” is the straight shell height of drying chamber. This is used for particle size range of 3 to 180 microns on D90. Used for allied production.

- Tall Tower Spray Drier : Having L/D ratio between 1:4 to 1:12. It is used to get particle size range of 180 to 2500 microns on D90 with higher bulk densities used for Fertilizers, Pesticides, Detergents etc.

- Spray Prilling / CongealingSystem : A Spray Drier can be used to dry molten feed by using cold gas instead of hot gas for drying. Typical uses are for various Pharmaceutical / molten waxes, Sodium Butyrate feeds, Poultry / Kettle feeds with necessary flavours for Animal fats.

- Jacketed Spray Drier : It is used to get desired produce, when the produce has critical glass transition temp., by circulating cold air through the jacket of drying chamber to keep the inner surfaces of the drying chamber at below glass transition temp. of the produce to avoid degradation of produce. Used for particularly API products, Fruit Juices, instant tea & coffee spray drying.