Spray Dryer Cum Spray Congealing System

Introduction

- Spray congealing is a simple and versatile method to produce particles of desired particle size distribution by making a molten feed with desired excipients.

- Spray Congealing System, otherwise known as spray chilling/ prilling, has attracted increasing attention because it is a simple technique, less time and energy consuming compared to other methods to obtain desired particulates with desired analytical results.

APPLICATIONS

- Spray Congealing has been used in a wide range of applications, including foods, nutraceuticals and pharmaceuticals applications, being used as oral/ non oral delivery systems.

Request a quote

Labultima’s SD/SC type of units have common drying chamber/ cyclone/ bag filter/ gas distributor/ aspirator blower & process control instrumentation.

- When the SD/SC unit is to be used as spray dryer, the unit is provided with hot gas system for drying the atomized droplets of feed.

- When the SD/ SC unit is to be used as spray congealer, the unit is provided with cold gas system for congealing the molten atomized droplets of the feed.

For spray congealing, the setup has built in feed melting facility along with heated molten feed conveying system through heated peristaltic pump to the heated spray nozzle.

- The unique feature of the SD/ SC unit is, it is a user friendly unit & can be used as a spray dryer or a spray congealer as desired by the scientist/ user, just by selecting either spray drying or spray congealing switch from the HMI.

- Similar arrangements of SD/SC unit concept have been successfully launched by Labultima upto 25 kg/ hr capacity.

Labultima has got inhouse facilities for demonstration trials on spray drying/ spray congealing on individual/ common units,

Ranging from lab level to kilo lab level to plant level upto 25 kg/ hr.

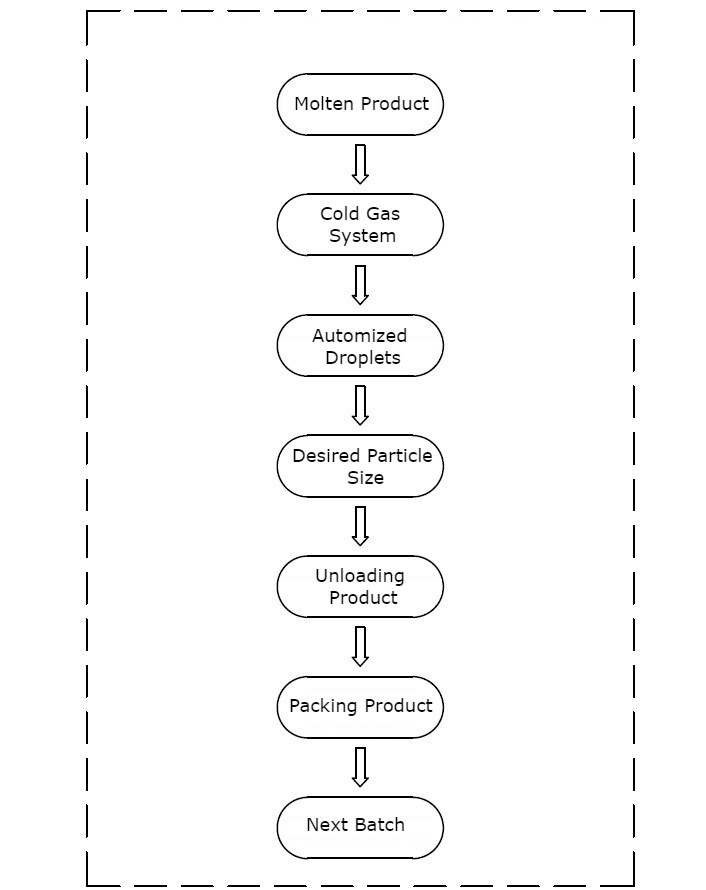

FLOW DIAGRAM