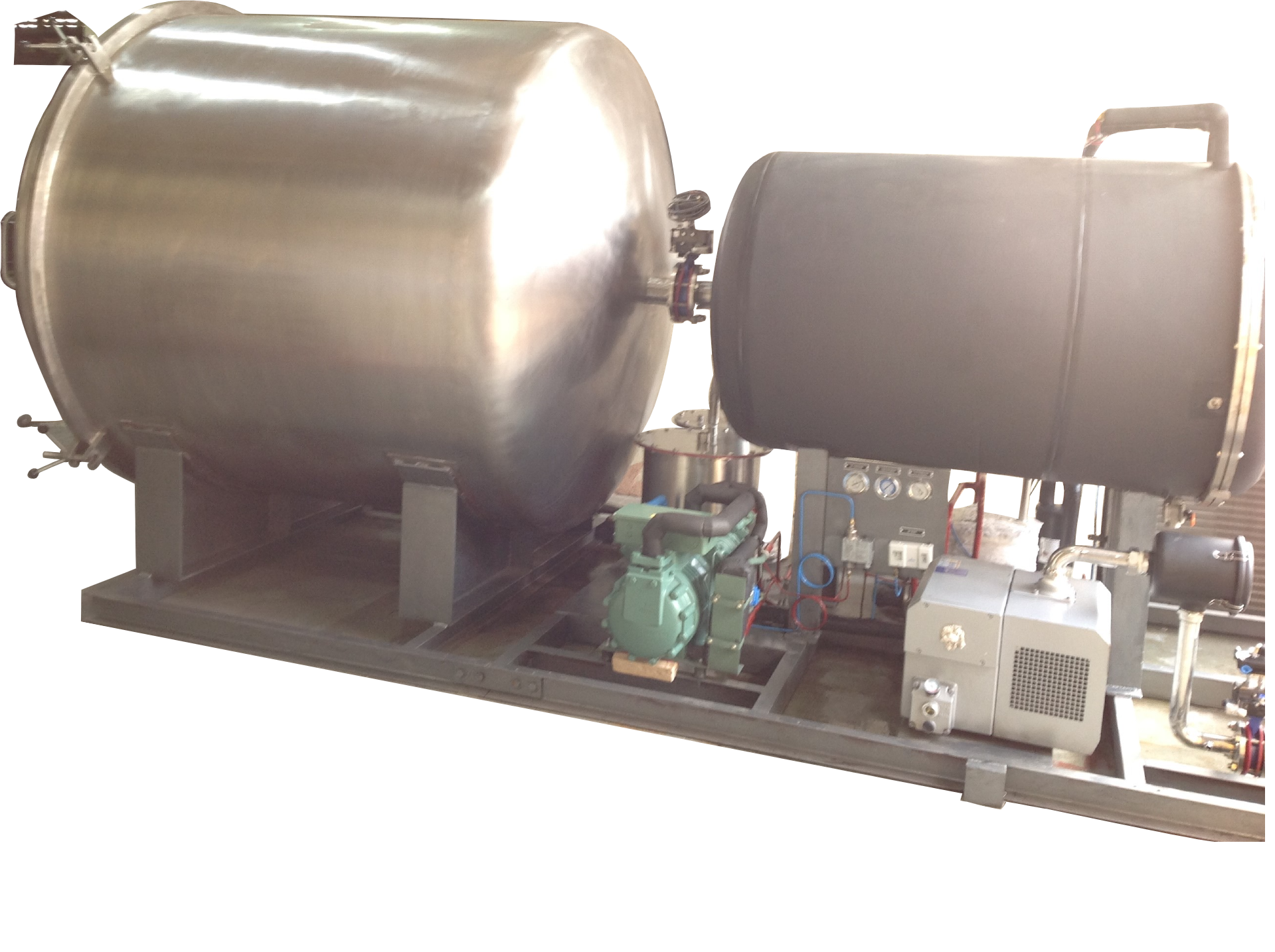

PLANT FREEZE DRIER-300

Introduction

Freeze drying is based on sublimation of a frozen solid sample, where the ice / moisture changes directly to vapour form, without going through a liquid phase. It is the only best method of drying to get < 1% residual moisture content in the produce. The produce is assured to have its original properties like taste / aroma and the analytical properties as applicable with minimum shelf life of > 12 months.

APPLICATIONS

- Foods – Soups, Upma, Poha, Dhokla etc.

- Fruits – Mango, Watermelon, Apple, Pineapple, Chikoo, Kiwi, Strawberry, Sugar Cane etc.

- Vegetables – Spinach, Sweet Corn etc.

- Beverages – Coffee, Tea, Aloe Vera, Cold Drinks etc.

- Milk Products – Milk, Curds, Custard, Flavored Milk, Baby Foods, Whey etc.

- Others – Yolk of Egg, White of Egg, Mixed Yolk +White of Egg, Misc Agro Products etc.

Request a quote

OPTIONAL FEATURES

- Indirect water Heater system (Induction).

- Hot water circulation pump.

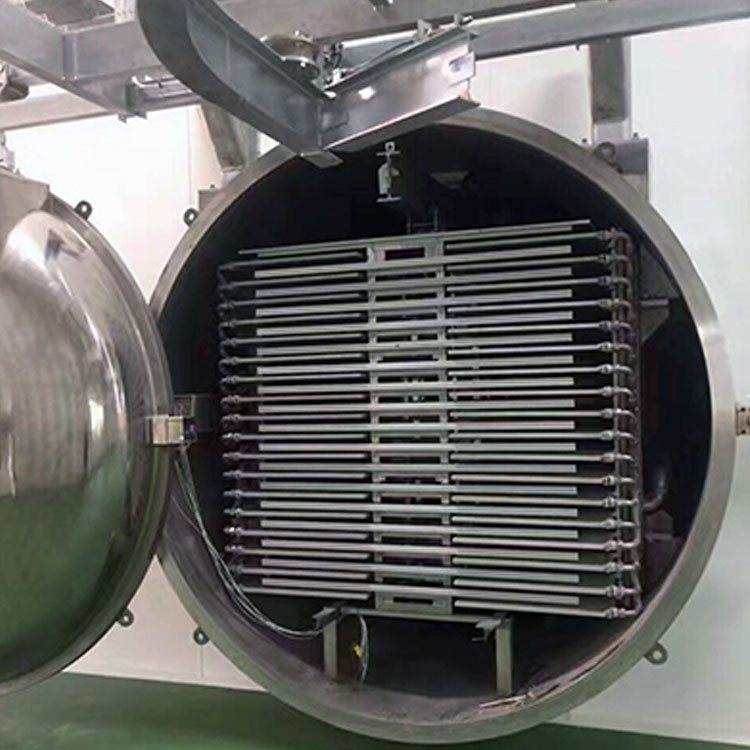

- Hot water circulation piping from hot water tank to hot water pump to heating plates below trays in the main drying chamber

- Main drying chamber.

- Input Trays – 40 nos.

- Trolley For Trays To Be Stored in cold storage.

- Vacuum pump – 0.1 m bar

- Water cooling for cooling jacket of vacuum pump

- Roots Blower

- Connecting piping from main drying chamber to condensation chamber through isolation valve and from condensation chamber to vacuum pump to roots blower – exhaust.

- Isolation valve

- Digital Pirani Vacuum Gauge

- Refrigeration compressor

- Condenser System

- Control Panel An operating / instrument panel with touch screen having running mimic diagram & screens with RS 485 port & two way communication between PLC & Touchscreen, with safety interlocks.

- Connected Load : 35.14 kW

- Consumed Load : 24.59 kW

- Space required : 3.00 MW x 8.00 ML x 3.00 MH

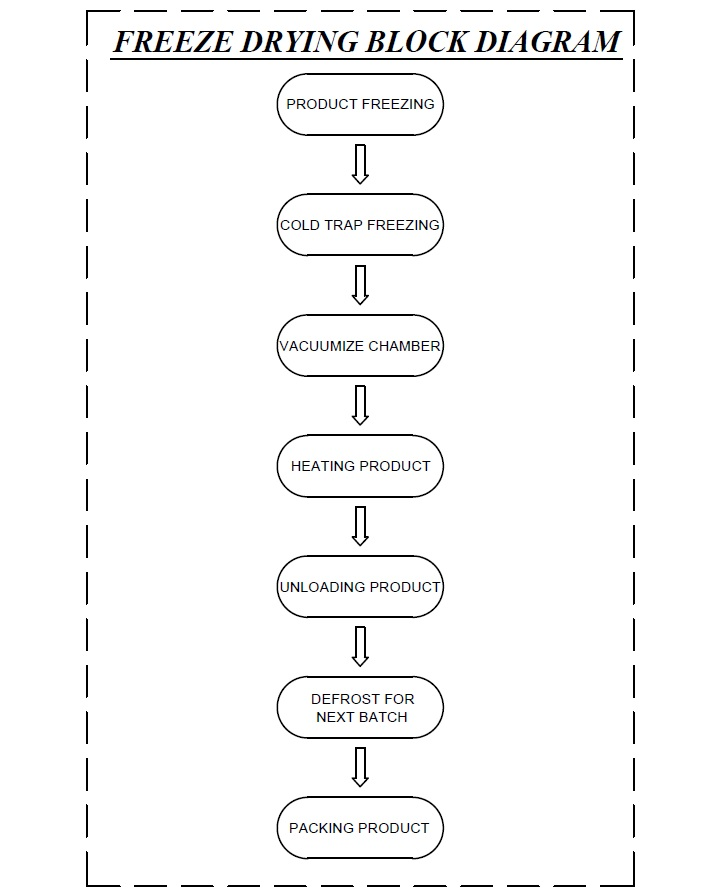

FLOW DIAGRAM